ABOUT US

ALPHA AUTOMATION LIMITED

Company since its establishment, in line with "the pursuit of all staff of both material and spiritual happiness at the same time, for customers, contribute to the progress of human society development" management idea, from the early auto parts factory developed into a professional research and development, manufacture all kinds of automobile welding jig, test fixture, robot workstation, Non-standard automation equipment and precision parts processing as one of the integrated manufacturing enterprises.

Under the unremitting efforts of all the staff, the company has undertaken many welding fixtures, inspection tools and automation equipment projects at home and abroad. At present, we have a professional design and quality team, a perfect production and sales team and first-class parts processing equipment.

In the future, we will share every product with all customers, and strive to create higher profits and value for customers, and provide customers with better services.

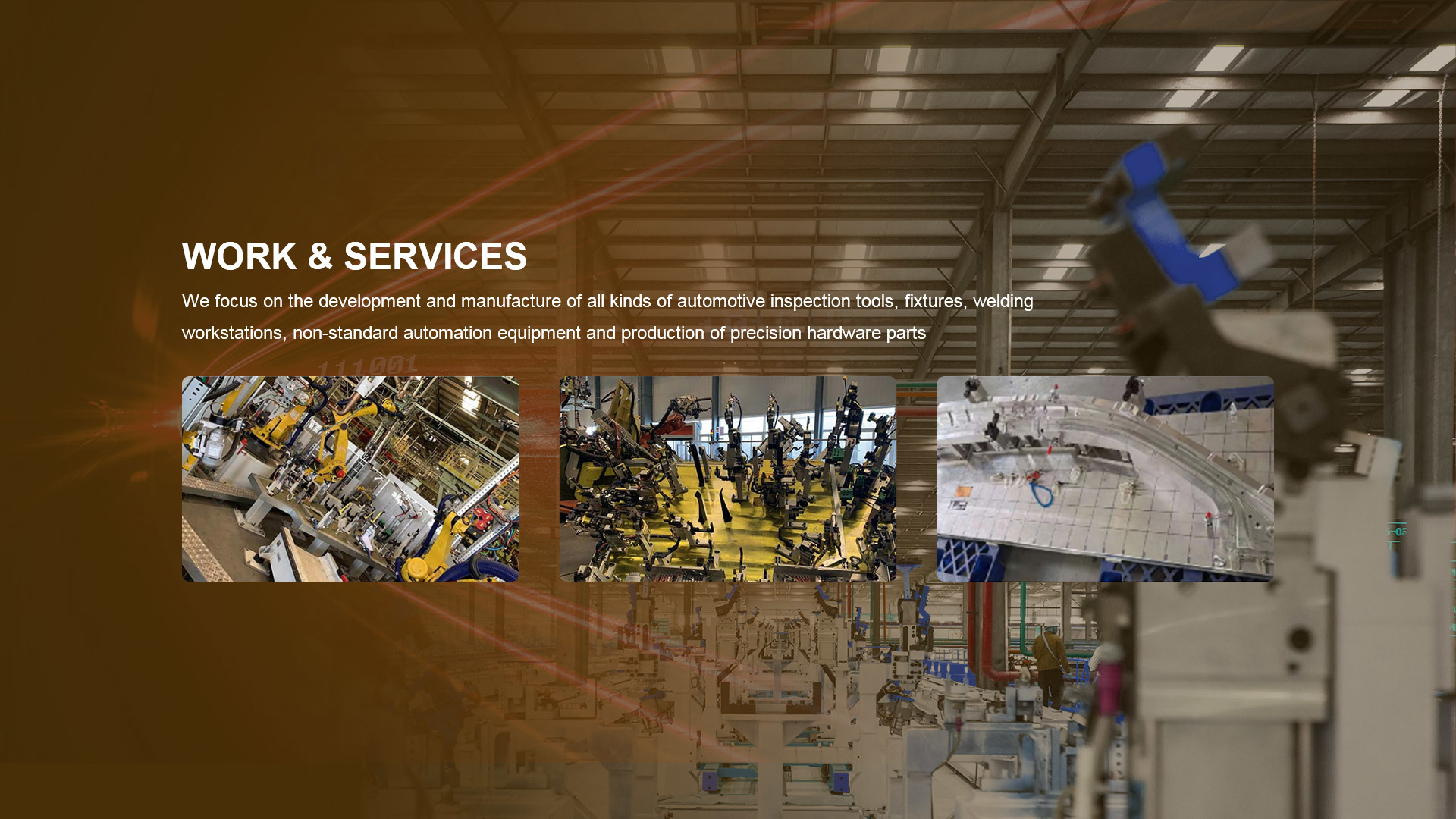

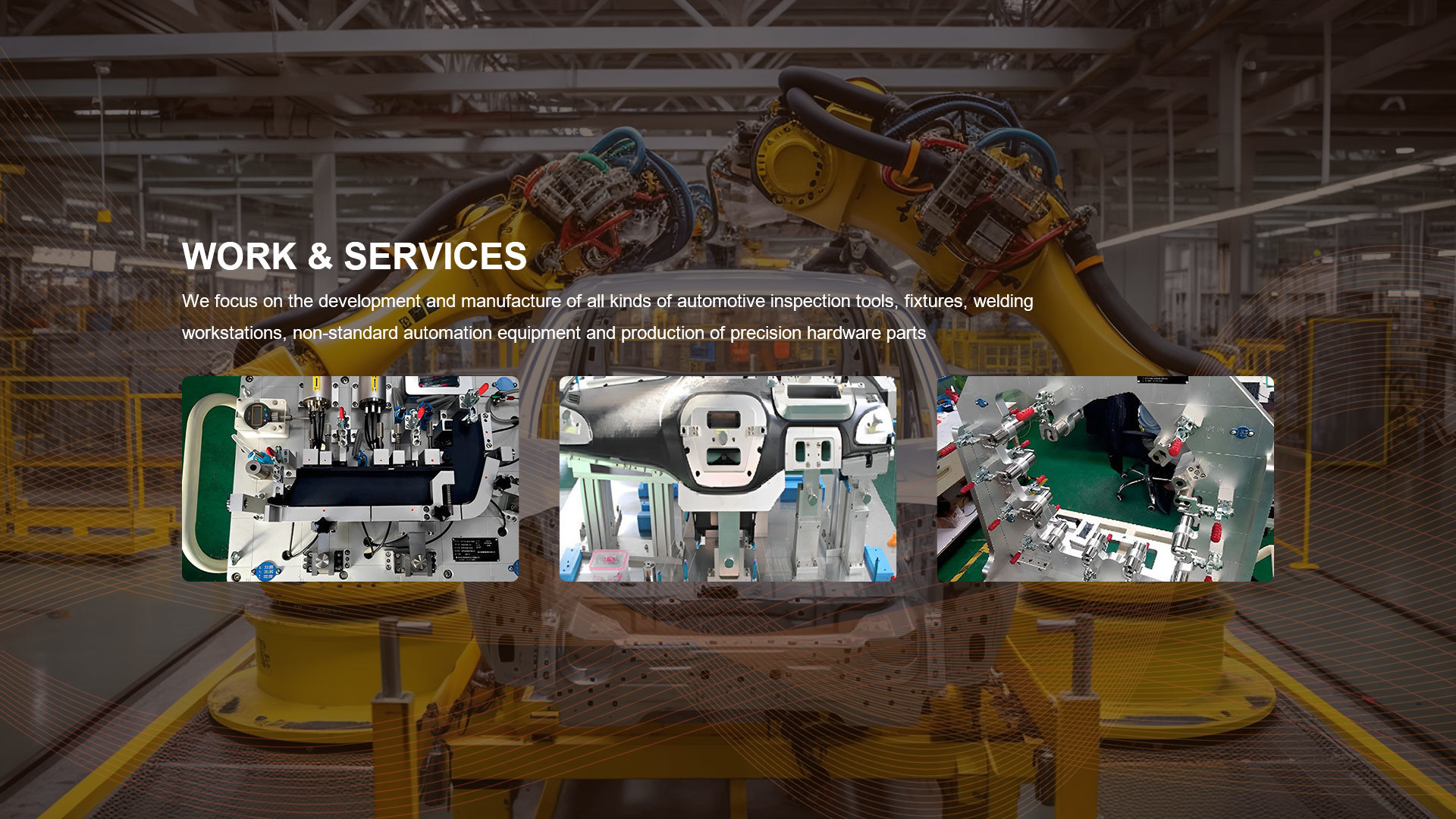

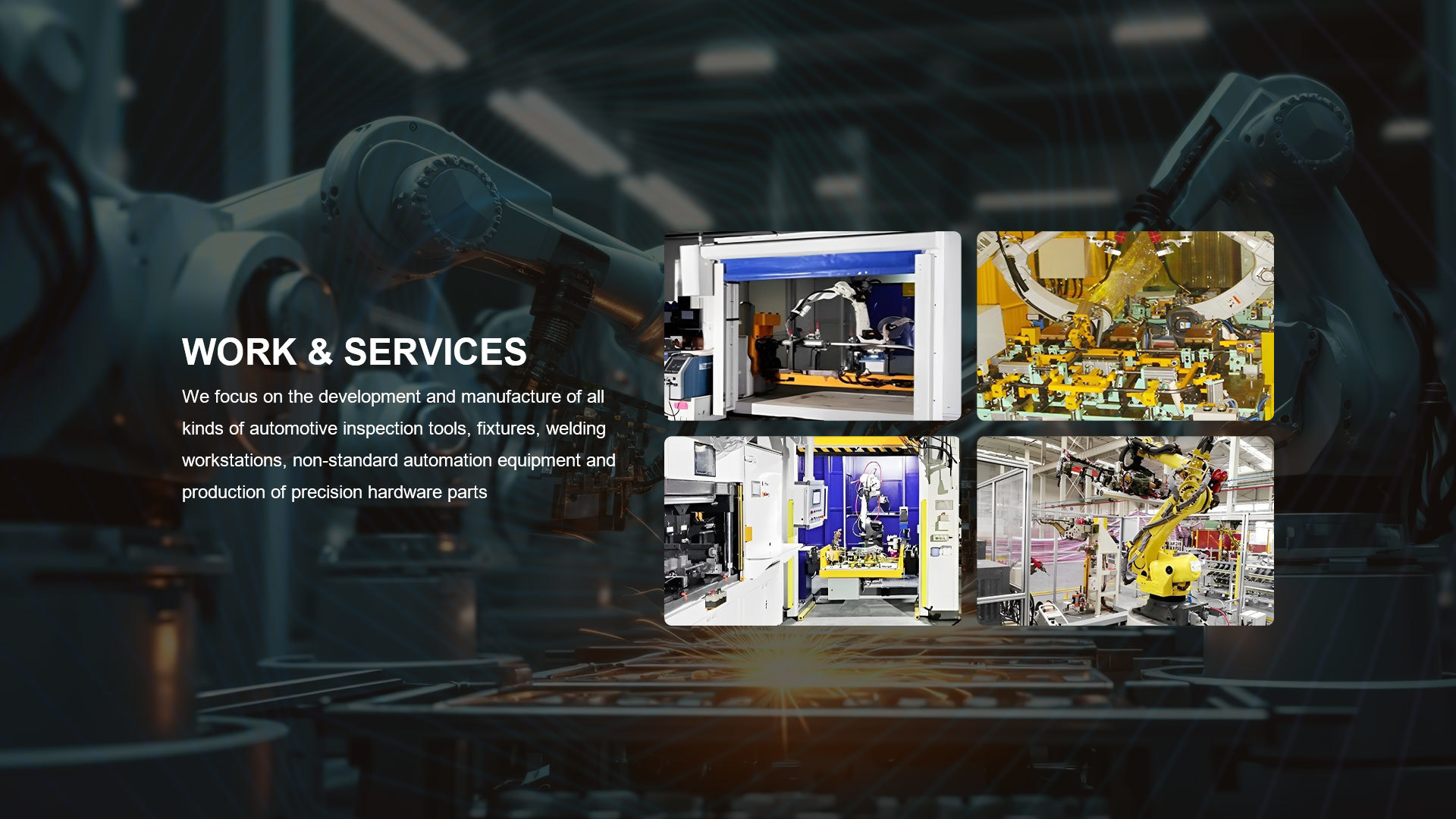

Focus on designing and manufacturing

Welding Jig

Checking Fixture

Robotic Welding Station

Non-Standard Automation Equipment

Precision Components Machining

ADVANTAGE

●Technical team’s rich in experience and quick respond to customer’s needs shows GW's strong technical competitiveness.

● Detailed project operating plan, risk control, process management and quality control ensure the project proceed smoothly.

● The professional and persistent attitude of the manufacturing team ensures that fulfill the project goal with high quality and efficiently.

Strong production strength

We attach importance to the use of technology and advanced equipment. At the same time, we are also committed to promoting the management of welding jig and checking fixtures. We have always maintained that we hope this continuous and reliable approach can provide more supporting measures to meet the customer's development plan. The company occupies an area of 8,000 square meters,Our experienced team total 120 members, 46 engnieers, 20 CNC operators , 2 CMM operators, 10 QA ,5 tool makers,5 sales, 10 officer and 12 grinder and milling machining operators. Our main equipment: CMM machine, precision grinding machine, milling machine, CNCmachine,wire cut and lathe. according to customer requires, we can provide resin, aluminum, steel to manufacture and we can provide the third party certification report if customer require.

Details >

Manufacturing experience

Our design team has rich experience and can always find innovative solutions from the needs and perspectives of customers, and ensure that the integration of related technologies allows all customers worldwide to obtain our world-class expertise to meet the needs of higher-end and more sophisticated products. They all have more than 10 years of industry design experience and are proficient in using UG, CATIA software, with a monthly production capacity of more than 80 sets. Our manufacturing team is also excellent, and production efficiency and quality can meet customer standards.

Details >

Quality assurance

The company has passed the ISO9001 international quality management system certification, established a perfect quality control and quality assurance system, trained a number of excellent quality management personnel and team. The introduction of the international leading three coordinate measuring equipment, mobile measuring equipment. With hexagon, TESA and other precision measuring equipment, its maximum detection range can be up to 4m, the highest measurement accuracy can be up to 1μm, can provide customers with important and reliable quality assurance.

Details >

Quality management process

Company since its establishment, in line with "the pursuit of all staff of both material and spiritual happiness at the same time, for customers, contribute to the progress of human society development" management idea, from the early auto parts factory developed into a professional research and development, manufacture all kinds of automobile welding jig, test fixture, robot workstation, Non-standard automation equipment and precision parts processing as one of the integrated manufacturing enterprises.

Details >

Ensure timely delivery

The company has a professional business team and project management in the industry to ensure that the delivery date of the customer's product is reached and that it is available 24 hours a day.

Details >

Super cost performance

We cooperate with excellent customers in the world to provide higher-quality products. In technology, we pursue continuous improvement to meet the needs of domestic and foreign customers.

Details >NEWS

Selection of automotive welding fixtures

2025-08-01

When selecting automotive welding fixtures, it is essential to comprehensively consider factors such as welding task requirements, material properties, structural design, precision requirements, drive mechanisms, cost, and production schedules. The following is a detailed analysis: 1. Define the welding tasks and requirements Welding type: Different welding tasks require different types of fixtures, such as spot welding fixtures, TIG welding fixtures, laser welding fixtures, and robotic welding fixtures. Part Characteristics: Consider factors such as part shape, size, weight, weld seam arrangement, and technical requirements, as these factors determine the complexity of the fixture structure. For example, large thin-walled welded parts, which are prone to deformation, require more complex fixtures to enhance rigidity.

Overall design of robot welding workstation

2023-08-15

The core of the welding robot workstation is a welding intelligent link with relatively high integration and synchronous operation of multiple intelligent mechanical facilities with the welding robot as the core.

What processes should be used for body welding?

2023-08-07

From the whole type of welding process, including manual arc welding, electroslag welding, stamping welding, brazing, friction welding, argon arc welding, carbon dioxide gas shielded welding, laser welding and so on.

What are the functions of the fixture

2023-04-08

Fixtures are also called fixtures. In a broad sense, any process in the process, the device used to quickly, easily and safely install the workpiece can be called a fixture. Such as welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc. Often referred to simply as a jig.

CONTACT US

Building 4, No.43, Chuangye Road, Changping Town, Dongguan City, Guangdong Province, P.R. China